ConSlitter Dual turret slitter

Two in One. For flexibility and throughput.

You always want to have the right answer to the changing requirements of your customers and at the same time increase your production efficiency? With the new ConSlitter you are optimally positioned for the future.

The combination of the proven KAMPF classic Conslit with the advantages of our modern turret technology enables you to reduce downtime and sustainably increase production throughput, especially when processing smaller batch sizes.

| Technical Data | ConSlitter CTRU |

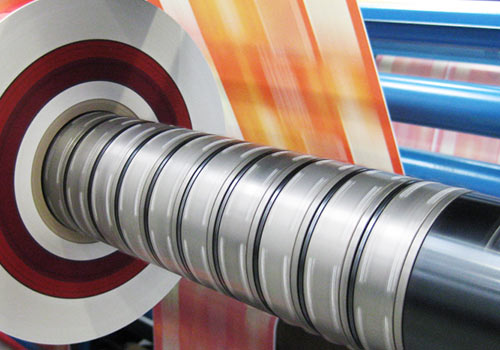

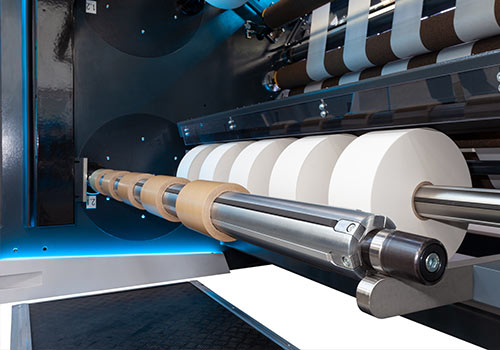

| Material | Material: Plastic films, refined papers, laminates |

| Material thickness | 10 – 500 μm |

| Material width | 1,450, 1,750 mm |

| Parent roll diameter | 1,000, 1,300 mm |

| Finished roll diameter | max. 630 mm |

| Finished roll weight | max. 600 kg |

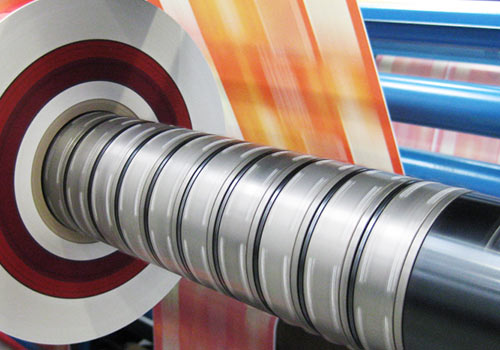

| Slitting system | Shear cut, blade cut |

| Slitting width | ≥ 50 mm |

| Winding cores | 3″ / 6″ |

| Machine speed | max. 800 m/min |

Efficiency.

Definitive strength of the ConSlitter.

Select from our extensive modular system the equipment features for your individual production and market environment.

- Reduce set-up times

- Automate roll logistics

- Realize data transfer

We certainly have the right solution for you.

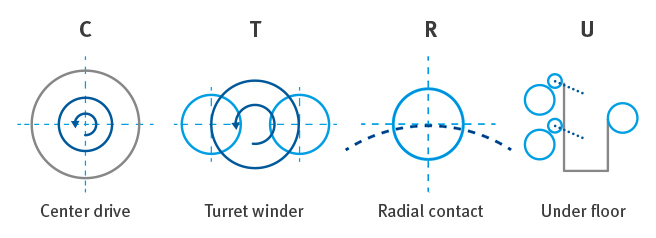

Illustrations of functionality

mm

Rewind Diameter

m/min

Machine Speed

Stagnation is regression.

Simply increase uptime.

Simple and reproducible

Laser Liner support fast and precise positioning of the rewind cores.

Fast and extendable

Save time and effort by using an integrated finished roll push-off system and extend this automation with a core positioning module on request.

Effektive and save

Do other important tasks while your valuable finished products are automatically transferred to further handling operations with the appropriate removal module and without further operator intervention and the ConSlitter is already producing again.

Security in a new light.

Industrial safety with a clear view.

Improved awareness brings more security to your everyday life. An intelligent lighting concept communicates the current status of the machine. A color lighting system that changes according to the situation allows you to monitor the status of the machine both in the area around and from a distance. The other redesigned and fully integrated safety devices also provide you with a constant overview, even at a safe distance.

A Modular System.

The right individuality for your application.

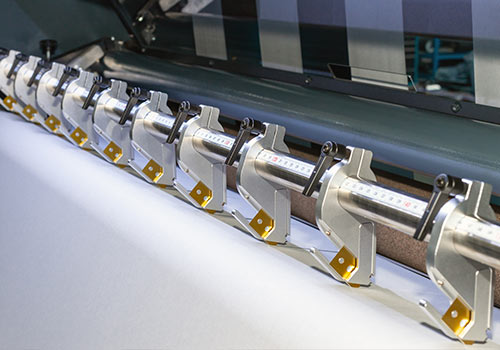

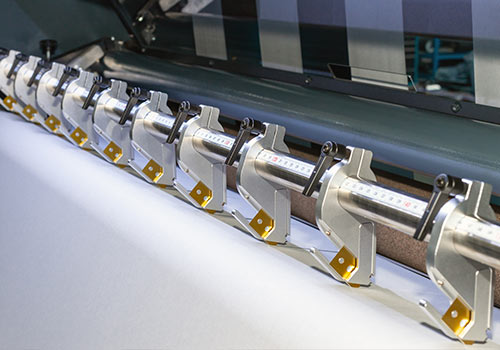

Shear cut

The all-rounder for high quality with long service life.

Optionally also with automatic positioning.

Razor blade cut

Reasonable and good. Optionally as groove or mirror cut.

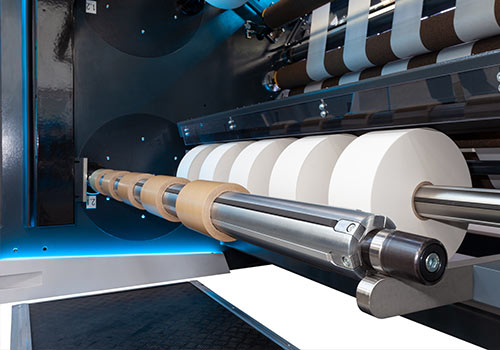

Expansion winding shafts

Safe production for simple applications.

Friction winding shafts

For reproducible quality and demanding materials.

Positioning aid

Time-saving and precise alignment for bottom knife and razor blade grooved bushes.

Splicing table and web control

High-quality web connections – made simple. Choose the optimum splicing table.

Expansion winding shafts

Safe production for simple applications.

Positioning aid

Time-saving and precise alignment for bottom knife and razor blade grooved bushes.

Friction winding shafts

For reproducible quality and demanding materials.

Splicing table and web control

High-quality web connections – made simple. Choose the optimum splicing table and the right web control system for your requirements.

Scissor cut

The all-rounder for high quality with long service life. Optionally also with automatic positioning.

Razor blade cut

The all-rounder for high quality with long service life. Optionally also with automatic positioning.

Beyond Slitting and Winding.

More than just a slitter. Productivity, availability and quality are key competitive characteristics. To ensure these features and thus your long-term success, we offer a wide range of value-added services for your machinery. With your decision for a new ConSlitter, you can also benefit from this individually tailored option for you.

- Automation solutions

- Material flow simulationso Connectivity of upstream and downstream processes

We offer highly efficient complete solutions, adapted to your needs and the requirements of your customers.

Our KAMPF Lifecycle Service is available throughout the entire life cycle of your machines.

Automation. One-stop added value.

- Increasing demand?

- Short delivery times?

- Cost pressure?

The demand for ever smaller production batches, higher throughput and increased overall plant efficiency places special demands on the performance of the machines and the handling of the parent and finished rolls.

KAMPF offers coordinated automation within and in the machine environment for optimum use of yours ConSlitter.

- Automated finished roll removal

- Advanced robot system

- Conveyor belts/transport carts

- Weighing deviceso Roll marking system

- Palletizing and packaging units

We are happy to support you with the development of tailor-made solutions thanks to our expertise in:

- Planning, project management and implementation

- Simulation (Digital Twin)

- Continuous communication and data flow

LifeCycle Services. Efficiency, availability and preservation of value.

Our offering for you. Lifelong and worldwide.

- Commissioning and service at site

- 24/7 online support via KAMPF Service Portal

- Spare parts services

- Individual service advice and maintenance package

- Retrofit packages for optimizing older machine

- Offers of second-hand machines

- Machine relocations

The KAMPF Academy also offers tailor-made certificate courses.

- Machine adjustment and operation / HMI, TIA and S7

- Maintenance and service

- Specific process engineering

- Slitting technology

Use this machine-specific service in our company, on site or via the World Wide Web.

Converting 4.0. Digital added value for you.

Converting 4.0 pursues the following principles as a holistic approach:

- Communication and integration of machines and processes during the digitalization of value chains begins with people.

- Information that creates knowledge and increases the efficiency of processes can not be achieved by a single person.

- We focus consciously on networks in order to actively design new technologies at the extremely high development speed of industry 4.0 and to generate the maximum benefit from generated data for your process.

- Machines and systems from KAMPF have always been an important, integral component in the individually designed value chains of our customers.

- With our innovative software platform the@vanced, we now inform you about the status of your production anytime, anywhere and conveniently, and enable you to communicate simply and data-based, beyond machine parameters.

the@vanced:

- Is an integrative software platform that networks the KAMPF machines, their integrated sensors and additional components.

- Gives you the possibility to collect important data, to visualize and analyze them individually.

- Communicates easily with your planning and control systems on site as well as with other external software platforms.

- Is the basis for big data applications, artificial intelligence, predictive maintenance and machine learning.

Your production at a glance. Fast and mobile.

the@vanced offers you digital added values based on three columns:

Smart Production. Be efficient!

- Status of the machine

- Life – machine data

- Dashboards

- Production results

- Productivity display

Smart Maintenance. Stay efficient!

- User manuals

- Maintenance videos

- Maintenance planner

- Digital machine model and spare parts catalogue

Smarter Operation. Increase efficiency!

- Big Data Lake

- Dashboards

- Data analysis

For further information